I’ve even built myself my own leather powered recliner. Final result came out super comfy.

The finished chair is my first attempt at upholstery and chair building. Wrapped in 2.5-3oz chocolate brown Italian leather (super soft to the touch) and accented with blue cow suede and champagne suede piping. From the ground up, the chair uses a Leggett and Platt 400-ez reclining mechanism, a 3/4″ birch plywood frame, jute webbing, and 8 way tied springs both back and seat. The seat uses 8″ springs and 6″ springs for the back. I topped it with 2.8lb density foams. 4″ of 30lb ILD foam for the seat, 2″ 23lb for the back and arms with 1″ 40lb foams for extra support in the back, the footstool, inside arms and anywhere I needed 1″ foam. Wrapped in ~1//2″ Dacron and leather.

I decided to do the back in a bright color and add some bright trim pieces on the sides and front after watching The Repair Shop on Netflix and looking up the host, Jay Blades, then seeing his website and being inspired by his beautiful chairs.

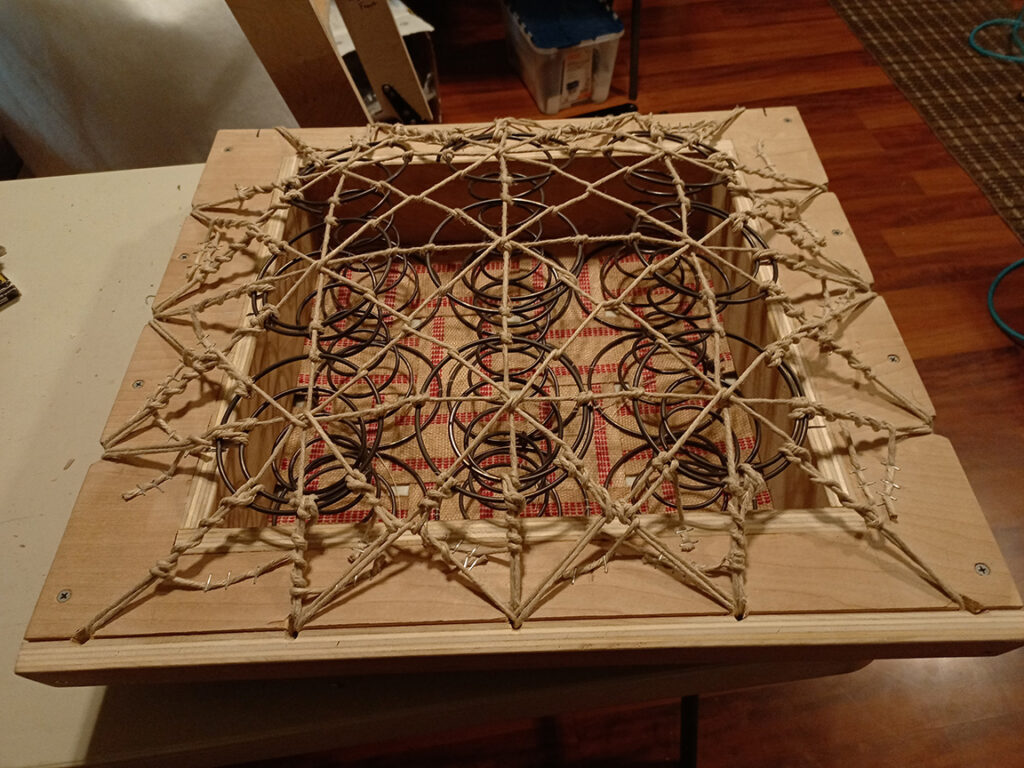

Originally I wasn’t planning to do springs. I didn’t actually even know they were a thing at first since I am so new to upholstery. I watched The Repair Shop on Netflix and seen Sonnaz Nooranvary doing tied springs and she inspired me to research the topic more, watch some tutorials, and to give it a try. It was tight building a frame that could have a drop down into the mechanism without hitting anything, but I did it.

The bottom view shows how I got all my twine tucked away. I cut grooves in the 2×4 sides so the twine could be stapled to the bottom of the plywood and I could have the 2x4s removed while I doing the tying. There is just enough space for the mechanism between the seat frame that it doesn’t seem to rub.

After I wrapped the seat in Dacron I took a photo and you can see the walnut dowels I placed on each side that the arms slide onto. This makes installing/removing the arms super easy.

On the back I added some pieces of 40lb foam in key areas for extra support. I just kept sitting in it and moving them around until it felt right. Then I added 2″ of 23lb foam on top of that. The foam added to the arms is 2″ 23lb on top and 1″ 40lb on the insides and on the front.

I decided to staple the back piece on from the top and wrap it around a small board then just velcro the sides of the back on. That way I can pull it up a bit still and get my hands up the skirt to unbolt the back if I need to.

The panels on the sides are velcro’d on and they give me access to the screws that hold the arms on. I made sure there was enough room to get the screwgun in there.